With an annual production of around 12 million meters, CLB is today one of the most prominent enterprises in Italy in the field of ennobling fabrics for the world of household linens and home furnishings. Since its inception in 1950, it has become a leader in fabric ennobling for the hotel and contract industries. CLB is part of Martinelli Ginetto Group since 2007. The acquisition has infused CLB with investments in human resources and machinery to expand their expertise in bleaching and finishing of tableware items, elevating quality and service and resulting in continuous growth, year after year. The plant spans an area of 40,000 square meters -19,000 of which are covered- in Arcore (MB), a strategic position for easy access to all the major highways of Northern Italy.

Every year, about 30% of revenue is allocated to structural investments. Advanced technology, optimization of processing times, operational flexibility, and staff expertise are essential requirements for CLB to achieve a high quality standard in line with customer's expectations and ensuring total satisfaction. The continuous integration between technological innovation and craftsmanship are at the basis of a finishing culture that CLB has held high since inception. Technology and computerization are complemented by operators' experience and expertise.

Orthogonal fabrics in cotton, linen, linen blend: CLB processes widths from 40 to 360cm and is the ideal partner for companies looking for quality, flexibility and service for dyeing, fine fabrics ennobling, yarn-dyeing, percale, satins and jacquards. Our machines can process large and small lots and, in addition to standardized production, they also allow maximum flexibility in prioritizing job orders. Our technical team has access to a lab for running chemical and physical tests, which allows CLB to create custom recipes and cycles to enhance fabrics according to their intended use.

With an annual production of around 12 million meters, CLB is today one of the most prominent enterprises in Italy in the field of ennobling fabrics for the world of household linens and home furnishings. Since its inception in 1950, it has become a leader in fabric ennobling for the hotel and contract industries. CLB is part of Martinelli Ginetto Group since 2007. The acquisition has infused CLB with investments in human resources and machinery to expand their expertise in bleaching and finishing of tableware items, elevating quality and service and resulting in continuous growth, year after year. The plant spans an area of 40,000 square meters -19,000 of which are covered- in Arcore (MB), a strategic position for easy access to all the major highways of Northern Italy.

Every year, about 30% of revenue is allocated to structural investments. Advanced technology, optimization of processing times, operational flexibility, and staff expertise are essential requirements for CLB to achieve a high quality standard in line with customer's expectations and ensuring total satisfaction. The continuous integration between technological innovation and craftsmanship are at the basis of a finishing culture that CLB has held high since inception. Technology and computerization are complemented by operators' experience and expertise.

Orthogonal fabrics in cotton, linen, linen blend: CLB processes widths from 40 to 360cm and is the ideal partner for companies looking for quality, flexibility and service for dyeing, fine fabrics ennobling, yarn-dyeing, percale, satins and jacquards. Our machines can process large and small lots and, in addition to standardized production, they also allow maximum flexibility in prioritizing job orders. Our technical team has access to a lab for running chemical and physical tests, which allows CLB to create custom recipes and cycles to enhance fabrics according to their intended use.

Today, CLB is known in Italy for its know-how in ennobling processes of double-width fabrics for household linens and home furnishings. Dyeing and ennobling of fine fabrics, satins and jacquards, precious flanders and mercerized canvases in vegetable fiber, cotton, linen and polyester/cotton blends, stretch, cotton and silk blend, wool, nylon, polyester, micromodal, lyoncell, viscose, bamboo.

CLB carries out the following processes:

It burns superficial fibrils to make a fabric weave perfectly clean and clear.

It eliminates the natural fiber coloring and any impurities it contains, to produce pure whites and optimal backgrounds suitable for dyeing and printing.

It gives the material greater shine and hydrophilicity, coverage of dead cotton, greater dimensional stability and dye affinity.

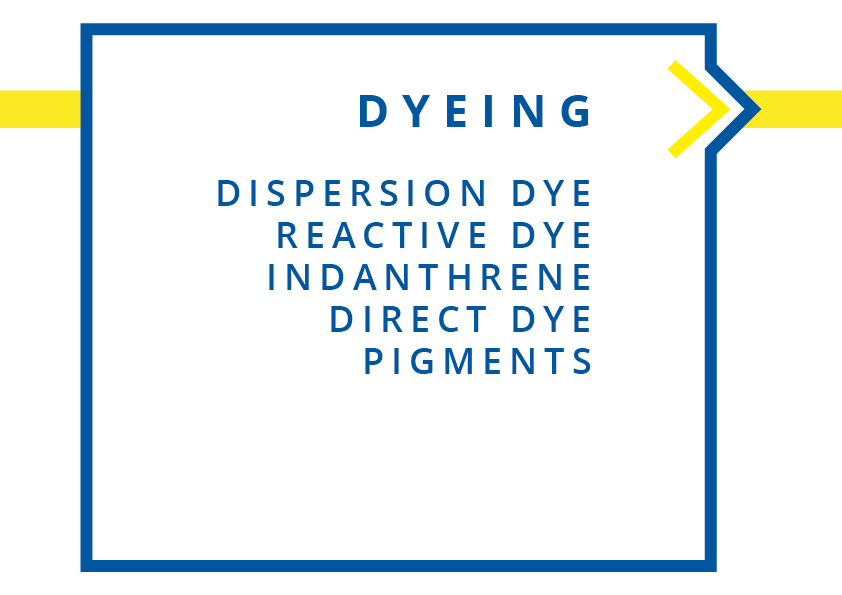

It gives the textile product a specific coloring that allows for product customization. Depending on the type of fiber and the target solidity, there are different classes of dyes and technologies that can be used (dispersion dye, reactive dye, indanthrene, direct dye, pigments).

The processing operations that improve a fabric's appearance, hand and properties (stenter, calandering, sanforizing, lapping, continuous tumbler).

The careful control executed during the entire production and ennobling chain converges at the inspection machines, where the last quality check takes place. The finished fabric is prepared in different formats according to customer needs: pallets, small rolls, pieces or large rolls.

Equipment and technologies in CLB constitute a wide and cutting-edge fleet which is constantly maintained and modernized to respond to market demands with quality and flexibility.